1095 CRO Van vs D2 D2 is superior to 1095 CRO Van Steel in edge retention, wear resistance, and corrosion resistance Better performance is expected since D2 is harder, but you will pay more to enjoy the benefits However, you will need more time and effort to give D2 a sharp edge than 1095 CRO Van Steel 1095 CRO Van vs S30VKABAR Modified Tanto $ The KABAR 1266 Modified Tanto is a new take on a classic blade design Made with our famous 1095 CroVan steel The 1266 has a Kraton G handle, a synthetic material that holds up in the elements The Modified Tanto comes with a rugged glassfilled nylon sheath Bestseller (1) It seems that '1095 CroVan' was originally a proprietary steel Sharon Seems roughly similar to O1 in composition (from A G Russell, AG Russell Knives Steel Guide AG Russell) Steel Carbon Manganese Chromium Nickel Vanadium Molybdenum Tungsten Cobalt 1095 CroVan 025 0161 006 — —

What Is 1095 Cro Van Steel Top 3 1095 Cro Van Knives Review Howtotactical

What is 1095 cro-van steel

What is 1095 cro-van steel-D2 Good edge retention, toughness, and sharpenability, D2 has been a popular knife tool steel dating back to WWII, and for good reason Keep your blade oiled as D2 is prone to rusting and corrosion This is one of those most ubiquitous steels in knives What is EN45 high carbon steel?

1095 Cro Van Steel Is It A Good Knife Steel

D2 is a tool steel, tool steels are harder, hold an edge better, harder to sharpen and are more brittle 1095 is high in carbon, softer, easier to sharpen, does'nt hold an edge as well, is more flexable and rust easily1095 CroVan(Sharon Steel) Based on 1095 steel, with the addition of small amounts of V, Mo, Ni, CrImproved wear resistance and toughness compared to 1095 KaBar and Bark river use this steel in their knives KaBar under 1095 CroVan name and Bark River as B developed by now defunct Sharon Steel It offers great edge retention and durability Unlike N690Co steel, D2 lacks enough chromium to qualify as stainless steel Apart from the better corrosion resistance, N690Co steel is easier to sharpen than D2 In fact, sharpening D2 is very beginner unfriendly You better learn the skill first before sharpening a D2 steel knife N690 vs N690Co

154cm steel is Americanmade steel, and it was developed in 1970 by Crucible It is one of the better steel knives available in the market 154cm is not powder steel;3 1095 High Carbon the knife steel that never quits This particular type of knife steel is, perhaps, the most loved by the survival/bushcraft community, as it's basically the workhorse of knife steel alloys This is the reason why most knives made of 1095HC (or even the metallurgically reinforced 1095Cro Van) are going to come with The steel is available in many knives today such as those produced by Bark River Knives Microstructure The microstructure of is somewhat coarser than simple steels like 1095 and O1, but finer than a steel like D2 D2 has a large amount of large chromium carbides that gives it very good wear resistance but somewhat poor toughness

The 1095 CS is a plain high carbon steel that will hold a nice edge and will rust readily The 4 SS is a martensitic stainless steel high carbon and also high chrome It is considered a SS steel though it will rust if not taken care of properly, but would be an order of magnitude better than 1095 CS in respect to rusting or corrosion from What is 154cm Steel?Becker Necker The Becker Necker is the quintessential neck knife Updated with 1095 CroVan steel, a locking sheath, and marked with the new BK&T KABAR stamps, the Necker is the same quality performer it has always beenonly better MOLLE compatible black hard plastic sheath with adjustable locking tab and 550 cord included

1095 Cro Van Steel Is It A Good Knife Steel

Pin On Knives I Like

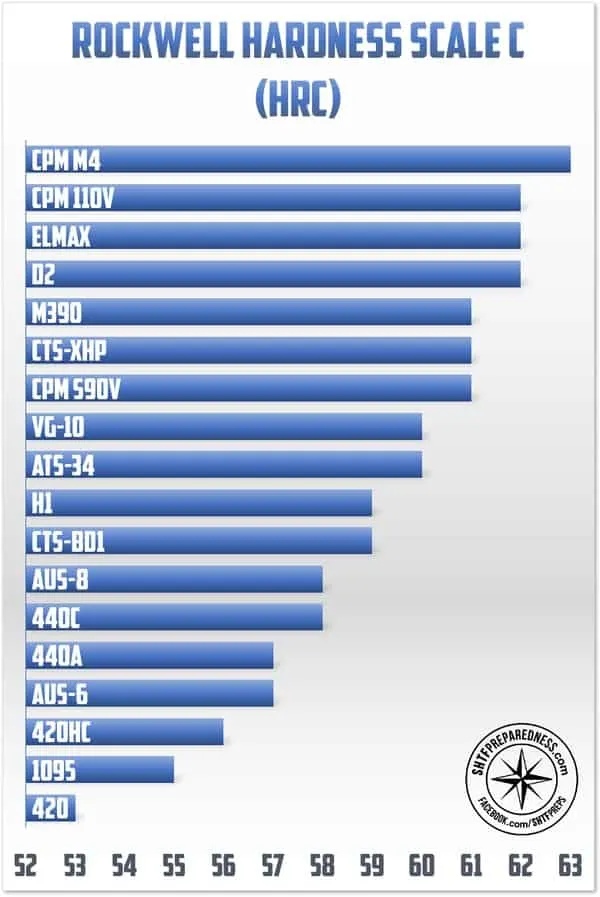

1095 is a decent steel that can have varying qualities depending on manufacturing variables (like most steel) but it typically has a Rockwell Hardness Value of around 55 which is a smidge on the soft side 1095 Steel for Knives 1095 steel, when used in knives, holds a great edge and is very easy to sharpen AISI steel review (1095 crovan steel) Materials steel is high carbon steel equivalent to 1095 steel with little addition of chromium The addition of chromium given it another name, "1095 crovan steel" This steel is commonly used in Mill rolls, fasteners, and many other applications mentioned below Get Price1095 Cro Van steel is lowend steel It's very great for knives It offers great edge retention, hardness, toughness, wear resistance, and very affordable, therefore if you intend to use it in a wet condition I wouldn't recommend it, it's carbon steel with low chromium AKA low corrosion resistance, so you' ill need to oil it and sharpen it, to keep it in shape and avoid rust

Spartan Blades Alala 3 75 1095 Cro Van Pro Grade Green Canvas Micarta Urbantoolhaus Singapore Pte Ltd

Ka Bar Knives 12 Catalog Pdf Document

The problem with the W series is that the carbon content varies so much However, if you have W2 like The New Jersey Steel Baron carries it will be a whole lot like 1095 because the only difference will be a little vanadium Just enough to form some vanadium carbides but not enough to effect the depth of hardening 1095 CRO Van vs D2 D2 is an extremely hard variant of steel That means it holds its edge better than 1095 CRO Van steel, and it's also much more wearresistant Also, like most other steels, D2 resists corrosion much more ably than 1095 CRO Van steel But there's a price to pay for this level of hardness This is why in general it is very difficult to innovate unless you are doing something very new, or making an enhancement For example it is easy to sell 1095 CroVan, as people will assume it is an "improvement" to the already existing steel However assuming you tried to use for example 4340 a lot of people would not know what it was

What Is 1095 Cro Van Steel Top 3 1095 Cro Van Knives Review Howtotactical

Is 1095 Cro Van Steel Good For Knives

EN45 is a high carbon steel grade that has unique strength and weldability capabilities This steel is also suitable for tempering and oil hardening En45 steel was introduced in the 1940s Moreover, EN45 isThe "1095 CroVan" steel used in the blades of contemporary KaBars has a hardness of 56–58 HRC, while the guard and pommel are made from sintered 1095 carbon steel Besides use as a fighting knife, the KaBar has proved useful as a utility knife, for opening cans , digging trenches , and cutting wood, roots, wire, and cable 1 1095 CRO Van steel vs d2 The higher carbide content in D2 gives it better wear/abrasion resistance It also has high chromium content and will resist rusting better than 1095 cro van steel However, D2 is harder to sharpen than 1095CV steel 1095 CRO Van steel vs s30v If you're more worried about staining and rusting, then you'd want to pick S30V and not 1095 crovan steel

In Praise Of 1095 Steel Bushcraft Usa Forums

The Ultimate Guide To Choosing The Best Knife Steel

Coated 1095 CroVan Surprisingly good edge retention, my KaBar BK11 was still shaving sharp after chopping through a small log! These are two very different steels, pretty much night and day in properties D2 is an extremely high alloy steel with a huge wear resistance and low toughness, while 1095 is a plain carbon steel with a very high toughness and low wear resistanceWasn't pleased with my Spyderco Endura 4's VG10 at first, until I put a 3,000grit edge on it and actually it's holding a

1095 Cro Van Steel Is It A Good Knife Steel

Kabar The Adventure Potbelly Heavy 1095 Cro Van Steel Blade Bonus Knife Ka5600

I tend to dislike stainless steels and prefer 1095 or other high carbon types I do like D2 steel however, although to me, it seems to be a bit tougher to get an edge on it not sure why Posted PM EDT Damascus is difficult and expensive to make so if the knife is < $100 it is probably crapThen use S30V steel What if you are creating a handful of more ordinary knives? While Damascus steel is often made with importance placed on aesthetics, strong, functional and durable knives can result from the proper choice of steel and careful forging Common grades used in the production of Damascus steel include 15N (L6), O1, ASTM 3E, 1095, 1084, 5160, W2, and Sources Midway USA

Edge Retention Test 1095 Cro Van On Bk7 Is There A Difference Youtube

Ka Bar Expands Two Fixed Blade Series

The 10XX (1045, 1095) Steels 1095 is the most common 10XX steel (or "high carbon" steel) used for knife blades Steel in the range are used for knife blades, although 1050 is more commonly seen in swords 1045 steel has less carbon (45%), where 1095 has more (95%), inversely 1095 has less manganese and 1045 has more The D2 Extreme is a KABAR, but it has a few distinguishing design choices First is the D2 steel used on the iconic 7inch clip point blade The D2 has a higher resistance to corrosion than the 1095 CroVan steel of other KABARs and keeps a razor sharp edge well The handle is also considered an upgrade by many D2 vs CPM S30V Conclusion In conclusion, picking the right steel comes down to cost and corrosion resistance Need a blade that is almost guaranteed never to rust?

Crkt D542gkp Bona Fide 3 52 1 4116 Pvd Plain Blade Adc12 Al Handle

1095 Cro Van Steel Is It A Good Knife Steel

"I already Used this Review in my other BK 7 reviews if you already did read it you can skip this part" The BK7 becker knife is one of the greatest combat tactical knives, it offers a 7" Clip point 1095 Cro van Steel Blade, the offers great edge retention, great toughness, and great wear resistance, it comes with a Grivory handle that offers toughness and a nonslippery grip, it hasKnife Steels AISI 1095, Sharon Steel 1095 CroVan Version 436 Home > Knives > Steels Knife Steel Chart Mobile Mouse over element names to get quick help on its effects in the alloy Mouse over multi alloy graph bars to see exact values Keyboard Shortcuts click to see the listAlthough those are getting pretty rare these days for hot work D2 is the most common one in that category, with 15%), then it's much more noticeable Oh, and as always, when considering 'durability' neither 1095, nor B are stainless steels, so will corrode if left wet etc

Ek Model 5 Fixed Knife 6 875 1095 Cro Van Steel Blade Black Gfn Handle Ebay

1

D2 is a tool steel that is hard to sharpen but will hold an edge longer and 1095 crovan steel is a good all around good knife steel a little easier to sharpen but will hold an edge all right I have both and like both, both will last a life time under normal circumstances with just a little care ra53fu28 · 1095 is a great steel 1095 (and 1084, 1070, 1060, 1050, etc) Many of the 10series steels for cutlery, though 1095 is the most popular for knives When you go in order from , you generally go from more carbon to less, from more wear resistance to less wear resistance, and tough to tougher to toughest steel review (1095 crovan steel) By hamza 0 69 steel is high carbon steel equivalent to 1095 steel with little addition of chromium The addition of chromium given it another name, "1095 crovan steel" This steel is commonly used in Mill rolls, fasteners, and many other applications mentioned below

What Is D2 Steel Is D2 Steel Best For Knives

Ka Bar Bk11 Becker Necker

Episode of GGL had Cedric and Ada, Peter, on to discuss lots of stuff, but his steel test insights need to be put into writing for future reference There are two parts to this, the method and the results Peter wrote the bulk of this post I wrote the Editor's Take In thick forms, like a fixed blade, 1095 is a tough, lowcost steel Used in knives since at least World War II, 1095 performance varies considerably with an abundance of tweaks in the recipe andIf you ever play with higher carbon steels (Over 1%;

Spartan Blades Machai 6 625 1095 Cro Van Pro Grade Green Canvas Micar Urbantoolhaus Singapore Pte Ltd

What Is 1095 Cro Van Steel Top 3 1095 Cro Van Knives Review Howtotactical

However, it is a highend, highcarbon stainless steel used for making a variety of knives for a variety of uses D2 steel is an alloy of high carbon and chromium giving it very superior hardness, wear, and corrosion resistance as compared to 1095 steel In terms of cost, Carbon steels are always cheaper than alloy steel but for long and sturdy use, D2 steel is preferable 1075 VS 1095 steelTWISTED SISAL MERCH THANKS TO MISHEARDKNIFEREVIEWS https//teespringcom/twistedsisalmerch Remember to subscribe for more lunacy hit the bell etc!http

Aisi Steel Review 1095 Cro Van Steel Bearing Steel

Kabar Jarosz Fixed Blade Knife 6 25 1095 Cro Van Black Brown Ultramid Plain Clip Point With Celcon Sheath 7503 Upc

By German DIN standard the D2's chemical equivalent is steel D2 is a good allround blade steel which dates to the 1940's While toughness and edge retention are above average, the D2 blades are harder to sharpen than most steels and due to not being stainless it takes more attention and care to keep the blade in good condition D2 is also much more resistant to corrosion than 1095 For these reasons D2 steel is a good for smaller folding knives, but is not ideal for large fixed blades such as dedicated choppers and large survival knives 1095HC1095 is a high carbon steel (instead of a stainless steel) commonly used in heavy duty tools D2 steel has a higher carbide content so it will have better wear resistance in abrasive materiel It is also very close to being a stainless steel, not quite So over 1095 it will resist corrosion better Versus 1095 it will be a bit more prone to chipping (depending on heat treat ect) 1095 takes an easy edge

What Is 1095 Steel Is 1095 Steel Good For Knives Top 1095 Steel Knives Review Howtotactical

Is 1095 Cro Van Steel Good For Knives

Re 1095 CroVan vs 440A Stainless While the durability will depend on how well they heat treat the blades, here's a good feel for the difference The 1095 CroVan will take and hold a great edge and will be good for a hard use knife, but will rust if permitted so keep a light sheen of oil on it in the field and in storageSteel BK 14 & Izula II are a 1095 steel and take a nice edge BK 24 is the D2 tool steel option, yet another plusBlade Coating BK14 is more textured than the Izula II, but very similarWeight, Size, and Usefulness I feel like both the BK14 & Izula II are too large for a dedicated neck knife, but they shine as a belt or pocket fixed blade 1095 What it is 1095 is a plain carbon steel, very common in folding and fixedblade knives designed for everyday use Advantages D2 What it is D2 is a carbon tool steel with a relatively high chromium content, prompting some to call it a "semistainless" steel Not as tough as the best carbon steels, it's tougher than most stainless

1095 Cro Van Steel Is It A Good Knife Steel

Buy Becker Knife And Tool The Knife Connection

The KaBar USMC fighting knife has a 7inch straight edge blade made of 1095 Crovan steel 1095 is a carbon steel, which is easy to sharpen and maintain It is one of the most widelyused steels in the KaBar knife line The handle is made of leather, and it come with a sheath which is also made of leather D2 Extreme Straight Edge The original D2 Extreme was an interesting release fundamentally, it hearkened to KABAR's famous USMC knife in terms of design, but with a more modern, blackcoated look, a rejigged handle, and D2 semistainless instead of the traditional 1095 CroVan carbon steel For some, however, the mandatory presence of

Foster Knives Best Knife Buying Guides

D2 Vs 1095 Steel Which One Is The Better Blade Material

Is 1095 Cro Van Steel Good For Knives

33 Metallurgy Ideas Steel Properties Steel 1095 Steel

Ka Bar D2 Extreme Fighting Utility Knife With Leather Sheath Army Navy Sales

Becker Kephart Fixed Knife 5 13 1095 Cro Van Carbon Steel Blade Walnut Handle Ebay

D2 Steel Complete Information Best Blade Steel For Hunting

Ranking The Steel Ranking Articles Knife Steel Nerds

Buy Ka Bar 2 1211 6 Blk Fighting Black Online In Vietnam B001h53q62

Aisi Steel Review 1095 Cro Van Steel Bearing Steel

5160 Vs 1095 Spyderco Forums

Spartan Blades Damysus 5 5 1095 Cro Van Pro Grade Black Canvas Micart Urbantoolhaus Singapore Pte Ltd

Aisi Steel Review 1095 Cro Van Steel Bearing Steel

Ka Bar Mark 1 Black 1095 Cro Van Steel Fixed Knife W Leather Belt She Atlantic Knife Company

Kabar The Best Amazon Price In Savemoney Es

How Good Is 1095 Steel

Ka Bar Dozier Folding Hunter D2 Coyote Tan Blade Steel Blue Zytel Handle Folding Knives Hunting Knives Blackbox Knives

Becker Knife Tool 3 25 1095 Cro Van Carbon Steel Blade Carbon Steel Handle Ebay

What Is D2 Steel Is D2 Steel Best For Knives

Is 1095 Cro Van Steel Good For Knives

The Ultimate Guide To Choosing The Best Knife Steel

D2 Vs 1095 Steel Which One Is The Better Blade Material

Http Zknives Com Knives Steels 1095 Cro Van Shtml

Crkt D542gkp Bona Fide 3 52 1 4116 Pvd Plain Blade Adc12 Al Handle

Ka Bar Fixed Knife 7 75 1095 Cro Van Steel Blade Black Rubberized Handle 1266 Ebay

Is 1095 Cro Van Steel Good For Knives Complete Steel Guide Knife User

What Is 1095 Cro Van Steel Top 3 1095 Cro Van Knives Review Howtotactical

Is 1095 Cro Van Steel Good For Knives Complete Steel Guide Knife User

1095 Steel Review Composition Properties Applications

Becker Eskabar Fixed Knife 3 25 1095 Cro Van Carbon Steel Construction Blade Ebay

Buy Ka Bar 1266 Modified Tanto Black Black Hard Plastic Sheath Straight Edge Online In Vietnam Bb8rl

Help Me Pick A Knife Page 1 Ar15 Com

Combat Tactical Knife Gear Roundup 5 9 Knifecenter Blog

1

1

Knife Steel Rust Testing 1095 8cr13mov D2 4hc Walmart And Y Start Youtube

Is 1095 Cro Van Steel Good For Knives

10 Knives For The Field And Beyond

O1 Vs Bladeforums Com

The Best Survival Knives In

All About D2 Steel Development Use In Knives And Properties Knife Steel Nerds

Cfk Usa Custom Handmade 1 4 D2 Black G10 Oregon Bushcraft Survival Tanto Knife Cfkcutleryco Tanto Knife Knife Survival Knife

Ka Bar Fixed Blade Knife 5 25 Clip Point 1095 Cro Van Carbon Steel Blade Fin Feather Fur Outfitters

Ka Bar Usmc Short Heinnie Haynes

D2 Steel Complete Information Best Blade Steel For Hunting

Best Budget Survival Knives 10 Affordable Fixed Blade Options

W2 Tool Steel Common Blade Steel For Knives Complete Info

The Ultimate Guide To Choosing The Best Knife Steel

Ka Bar Fixed Blade Knife 5 25 Clip Point 1095 Cro Van Carbon Steel Blade Fin Feather Fur Outfitters

1095 Cro Van Steel Is It A Good Knife Steel

Spartan Blades Alala 3 75 1095 Cro Van Pro Grade Green Canvas Micarta Urbantoolhaus Singapore Pte Ltd

The Best Ka Bar Knives For Tactical Edc And Outdoor Use Gear Hungry

5160 Vs 1095 Spyderco Forums

1095 Cro Van Steel Is It A Good Knife Steel

Amazon Com Ka Bar 1281 D2 Cuchillo De Pelea Extrema Deportes Y Actividades Al Aire Libre

What Is 1095 Cro Van Steel Top 3 1095 Cro Van Knives Review Howtotactical

Ka Bar Knives Ka Bar Modified Tanto Knife Fixed Blade 18 Off W Free Shipping And Handling

D2 Vs 1095 Steel Which One Is The Better Blade Material

What Is D2 Steel Is D2 Steel Best For Knives

Ka Bar Combat Kukri 1280 Machete Advantageously Shopping At Knivesandtools Com

Ka Bar Ussf Blue Space Bar Fixed Blade Knife 1313sf 87 84 Picclick

Buy Kabar Mark I Fixed Blade Knife 5 13 Blade Hard Plastic Sheath 1095 Cro Van Black Steel Black Kratong Handle Plain Edge 2221 Upc Online In Italy B07hjvmrxc

Ka Bar Bk14 Cuchillo Y Herramienta Estilo Becker Eskabar Herramientas Y Mejoras Del Hogar Amazon Com

1095 Cro Van Steel Is It A Good Knife Steel

Ka Bar Dozier Folding Hunter D2 Coyote Tan Blade Steel Blue Zytel Handle Folding Knives Hunting Knives Blackbox Knives

All About Ka Bar Knives Knife Depot

Ka Bar Knives Ka Bar Modified Tanto Knife Fixed Blade 18 Off W Free Shipping And Handling

Urbantoolhaus Singapore Innlegg Facebook

Handmade Full Tang Knife D2 Steel Bushcraft Knife Scandi Grind Bushcraft Hand Crafted Knife In 21 Bushcraft Bushcraft Knives Knife

Amazon Com Cabeza De Perro Fija De 1º Aniversario 1095 Cro Van De Acero Al Carbono Protactical Elite Cuchillo 4167rt Libro Electronico Gratuito Herramientas Y Mejoras Del Hogar

Buy Ek Model 5 W Sheath 1095 Cro Van Steel Us Online In Turkey B01b0x07p8

Ka Bar Classic Military The Aragorn Knife Mad Ogre

Is 1095 Cro Van Steel Good For Knives

Ka Bar Becker Kephart Bk62 5 125 1095 Crovan Blade Walnut Handle Fixed Blade Knife Knife Cold Steel Knife

The Best Survival Knife For The Money Shtf Dad

1

Hjgjb9jgkln26m

What Is 1095 Cro Van Steel Top 3 1095 Cro Van Knives Review Howtotactical

No comments:

Post a Comment